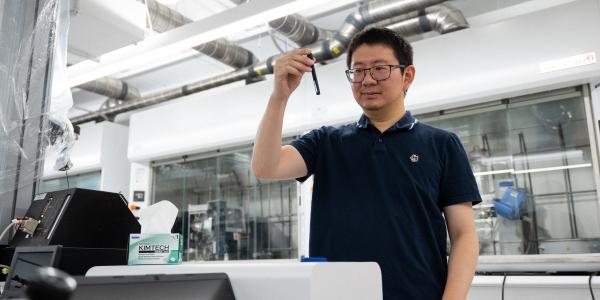

Inspired by biology, the chemist develops fabrics, gear, and materials that respond automatically to stress, heat, and pressure.

Why might a chemist take an interest in a hole forming at the knee of a pair of jeans? For Chenfeng Ke, an associate professor of chemistry, it was an opportunity to rethink what fabric can do. What if those threads were a bit stronger or, better yet, a bit smarter?

“Smart jeans” are just one of the innovative products Ke has in mind. Looking to biology as his main source of inspiration, Ke uses 3D printing and other techniques to build novel materials with many potential applications, ranging from medicine to clothing. In April 2025, he proposed a new generation of smart fabrics at A&S Innovates, Arts & Sciences’ inaugural research pitch competition. With no shortage of natural compounds for him to emulate, there are many more intelligent materials to come.

Ke spoke to the Ampersand about his work and the potential of smart chemistry.

How do natural materials inspire your work in chemistry?

We look at the fundamental design principles of DNA, enzymes, proteins, and other biological marvels to understand how they function. We’ll even study whole structures, such as bamboo stalks or crab shells. Then we use 3D printing to attempt to create materials with similar functions. We can’t mimic biology perfectly, mostly because nature doesn’t use 3D printers. But we can get close in some cases. The printer allows us to produce materials in bulk, so we can quickly test their properties for a variety of applications.

One of the major thrusts of the lab is producing so-called “smart” materials, which are materials that are sensitive to external inputs such as heat, light, and pressure. The responses are reversible, so they go back to normal when the inputs are removed or reversed. This ability is very common in nature. Human skin is a sort of smart material.

What are some examples of smart materials in your lab?

A lot of the work in my lab centers around hydrogels, a family of materials that are mostly water trapped within three-dimensionally connected carbon chains. The resulting materials are very strong but flexible, much like living tissues.

We’re currently looking at the possibility of creating smart textiles, special polymers that could have applications for everyday clothing as well as protective equipment. The textiles are made of sugars combined with polyethylene glycol, the active ingredient in stool softeners, which together form a fabric of polymer beads that is extremely durable and stretchy.

The “smart” part is that such textiles could strengthen themselves in response to stress. To see why this is important, consider blue jeans. The knees always wear out first because that’s where the stress is. In jeans made with smart material, the polymer beads would automatically strengthen in the area where it matters most.

We’re also thinking about helmets, such as the type a soldier would wear. Helmets need to absorb shock but shouldn’t be so hard that they’re uncomfortable to wear. A smart helmet wouldn’t necessarily be able to stop a bullet, but if a soldier is hit on the head with a blunt object, the helmet could instantly stiffen itself to protect the brain.

What other kinds of materials have you created?

We’re using nature as inspiration to make lightweight, durable, and porous crystalline materials for water purification. If you use iodine or another chemical to treat water, you want to remove the chemicals after it has killed bacteria or viruses. Our material traps iodine but lets water pass through. We're actively working with NASA to develop more efficient water-filtering devices for space travel.

We’ve also created a substance made of nanotubes that can precisely separate antioxidants from fruit or vegetable juice. This could be useful for collecting and preserving antioxidants for supplements or food additives.

What’s your role in the actual production of new products?

My lab doesn’t create fully formed products that are ready for consumers. We want to discover and produce innovative materials that engineers and others can use to make better, cheaper, and more efficient products. We prove that a material can do a particular job, and engineers find a way to bring that function to the real world.

What are your plans for the future?

I came to WashU in 2024, so I’m still working on building collaborations with researchers at McKelvey, the School of Medicine, and elsewhere on campus. Being a part of this scientific community will help me come up with more interesting research questions. WashU is at the leading edge of innovation, which is exciting.